rockwell hardness c testing calibration|rockwell hardness test diagram : purchasers The revision of E 18 requires that all performance verifications of Rockwell hardness indenters and hardness machines must be made using test blocks calibrated traceable to the Rockwell . Description . In The Man from the Window, navigate through an intense narrative-driven game, assuming the role of Mama Rabbit.Your objective is to protect your family from a dangerous man prowling your .

{plog:ftitle_list}

web9 de mai. de 2023 · Phoenix. Phoenix is not only a mythical being, but also a constellation seen in the southern sky. In 2023, Paris Hilton named her baby boy Phoenix which may cause it to trend upward for both boys and girls. .

The revision of E 18 requires that all performance verifications of Rockwell hardness indenters and hardness machines must be made using test blocks calibrated traceable to the Rockwell .This document provides guidance for calibration and testing laboratories involved in hardness measurements, as well as their assessors. It has been produced to improve harmonization in .

Learn all you need to know about Rockwell hardness testing – including test definitions, test calculations and insight into Rockwell hardness testing machines and HRC hardness testers – with knowledge and expertise from Struers, the . 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the verification .In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to eliminate effects from the roughness of the specimen surface (e.g., grooves on the specimen) as well as measurement errors . The purpose of this Guide is to explain the causes of variability in Rockwell hardness test results and to supplenment the information given in test method standards with .

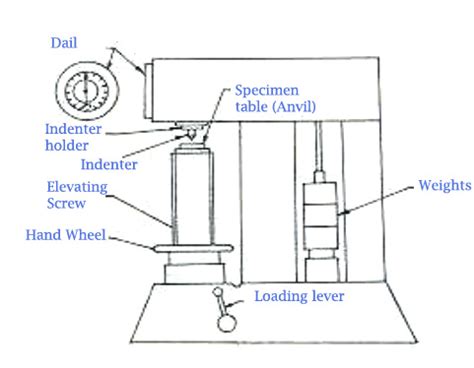

rockwell hardness testing machine diagram

Rockwell hardness testing is a common way to ensure the material response to heat treat is conforming and is required by applicable industry and prime specifications. 3.1.7.3 portable Rockwell hardness testing machine a Rockwell hardness testing machine that is designed to be transported, carried, set up, and operated by the users, and that measures Rockwell hardness by the Rockwell indentation hardness test principle. 3.1.7.4 movable Rockwell hardness testing machine a Rockwell hardness testing machine .Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing

Set includes six files and a chart to convert to Vickers scale. It is an economical way to determine the hardness of steel on the Rockwell C-scale.Handles are marked with Rockwell hardness values. If a file can scratch your material, then your material is softer than the file. If a file cannot scratch your material, then your material is harder than the file.ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application.We offer NIST Traceability on C Scale only. Twin Scale Hardness Testers which include C, B, and A Scales plus 15, 30, 45 N and T Scales. To certify your Superficial Rockwell Hardness tester to the current revision of ASTM E18, you are required to have certified penetrators.Rockwell C Scale, Hardness Calibration Test Block. C62 Hardness, High Hardness Range Description, 2 Piece. MSC# 00444737. Mfr# HTB00062B. 0. In Stock. Quantity. Add to Cart. Compare Price. 8.61 / ea. Made in USA. Rockwell C Scale, Hardness Calibration Test Block. C45 Hardness, Mid Hardness Range Description, 2 Piece .

Verification should be performed by an accredited verifying agency and the report should follow and reference ASTM E18 Rockwell test method. Hardness testing is an important and useful tool in materials testing, quality control and acceptance, and performance of materials. . Rockwell Hardness Testing Calibration Kits; Rockwell Hardness Testing Theory. Rockwell hardness testing has several indenter types which in turn require separate major loads (kg). Figure 1 reflects common Rockwell scales used and their corresponding major loads. Figure 1. When Rockwell hardness testing, a minor load of 10kg is applied to the indenter used on the material being tested.[1] Sawla A., Uncertainty of measurement in the verification and calibration of the force measuring systems of testing machines.Proceedings of the Asia-Pacific symposium on measurement of force, mass and torque (APMF), Tsukuba, Japan, November 2000 [2] Wehrstedt A., Patkovszky I., News in the field of standardization about verification and calibration of .

Calibration Client Portal. CPT Bulletins. Press Releases. Forensic Assignment Form. ISO 9001:2015 Registration. ISO/IEC 17025:2017 (A2LA) 1888–01: Mechanical Testing. . An indentation process, Rockwell Hardness testing is straightforward and uncomplicated in practice. Using a diamond cone or sphere-shaped indenter, a minor load is applied .4 APPLICATION TO THE ROCKWELL C SCALE: EVALUATION AND PROPAGATION OF . verification and calibration of industrial hardness testing machines. 1.4 Figure 1.1 shows the four-level structure of the metrological chain necessary to define and disseminate hardness scales. Note that at each level both direct calibration and indirect

CertronixWEST has provided outstanding calibration services and sales since 1992. With over 35 years of Rockwell Hardness testing experience, we are a leader in our field. Our territory covers California, Arizona, Nevada, and Utah. With over 200 customers, CertronixWEST strives to give its customers outstanding service at a competitive price.

The Rockwell hardness test continues to be applied as a tool for assessing the properties of a product while the tolerances on the acceptable material . test block. The NIST calibration measurements are indicated by the solid circles, and the locations of the certified values for untested locations are 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the verification of machines for Rockwell hardness testing (Part B) and the calibration of standardized hardness test blocks (Part C).Shop Rockwell C Scale, Hardness Calibration Test Block Set at MSC Direct top provider of high quality products. Starrett. Rockwell C Scale, Hardness Calibration Test Block Set-4 Piece. MSC # 83671750 Mfr # 67969. Write the .

ISO 6508-3:2005, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks . 3 General conditions Before a Rockwell hardness testing machine is verified, the machine shall be checked to ensure that it is properly set up in accordance with the manufacturer's instructions:We are ISO 17025 accredited to perform testing of your hardness specimens in the Rockwell, Superficial Rockwell, Knoop/Vickers microhardness, and Brinell ranges. We are also a distributor of high quality hardness test blocks. .Rockwell Hardness Testing calibration procedures mandate the use of Diamond Indenters that are verified for geometrical and performance standards, per ASTM and ISO requirements by an accredited laboratory. Each Indenter is assigned a certificate of compliance assuring traceability for that indenter.Bring material right to your bench to measure its hardness. These testers use a carbide indenter to take accurate Rockwell hardness readings every time. They come with a calibration certificate traceable to NIST that states they’ve passed a test for accuracy. With a durable metal body, these testers stand up to many environments, from heat treat facilities to workshops to .

Metallic materials — Rockwell hardness test — Part 2: Verification and calibration of testing machines and indenters 1 Scope This document specifies two separate methods of verification of testing machines (direct and indirect) for determining Rockwell hardness in accordance with ISO 6508-1, together with a method for verifyingThe Buehler Wilson® Reference Block Laboratory in Binghamton, NY, has achieved accreditation to ISO/IEC 17025 by A2LA (American Association for Laboratory Accreditation) for Rockwell, Knoop, Vickers and Brinell hardness test blocks and indenters. A2LA is in full conformance with the standards of the International Organization for Standardization (ISO) and the International .Buehler's industry leading hardness testing blocks ensure accuracy, integrity, and traceability in hardness testing processes. The comprehensive range of scales and blocks, associated with Rockwell, Brinell, Vickers and Knoop testing. . Rockwell Hardness Testing Calibration Kits;All Wilson Rockwell hardness test blocks are calibrated in the Wilson Hardness Calibration Laboratory in Binghamton, NY. The Wilson lab is accredited to ISO/IEC 17025 by A2LA and the testers used in the calibration process undergo a stringent monitoring process using NIST traceable devices.

ISO 6508-1:2015, Metallic materials — Rockwell hardness test — Part 1: Test method ISO 6508-3:2015, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks 3 General conditions Before a Rockwell hardness testing machine is verified, the machine shall be checked to ensure that it isRockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the principle of the differential-depth method. Here, the indenter makes a residual depth called the indent and it is .

5.1.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. The significant difference between the two test classifications is in the test forces that are used. For the Rockwell hardness test, the preliminary test force is 10 kgf (98Sun-Tec along with Clark Instrument and Detroit Testing Machine specializes in hardness testing, Sales, Service and Calibration. We offer precision equipment for testing such as: Rockwell Type (both bench and portable), Brinell (both bench and portable), Micro and Macro Vickers Indentation, Ductility, Tensile and Compression. We also retrofit control systems for .

rockwell hardness testing chart

rockwell hardness tester procedure pdf

rockwell hardness tester calibration cost

coefficient of friction tester for rubber

WEBPlataformas pagando | https://mar777.vip/ | Facebook. Log In. Forgot Account? https://mar777.vip/?id=98179505 Lançamento de hojee,esta pagando de mais ganhos .

rockwell hardness c testing calibration|rockwell hardness test diagram